Kettle reboilers are the cornerstone of many industrial processes, ensuring the separation of components in distillation columns. However, their continuous and efficient operation depends heavily on their reliability and proactive maintenance. Problems such as fouling, flow-induced vibrations (FIV), and the accumulation of non-condensable gases can severely degrade their performance, increase operating costs (OPEX), and, most […]

Sin categoría

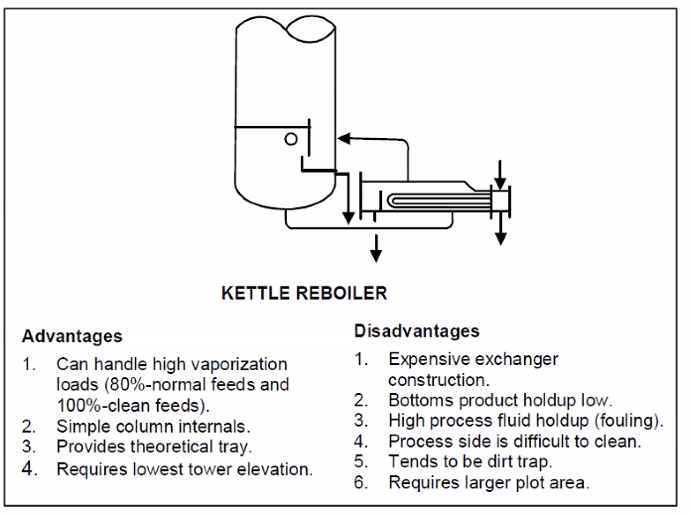

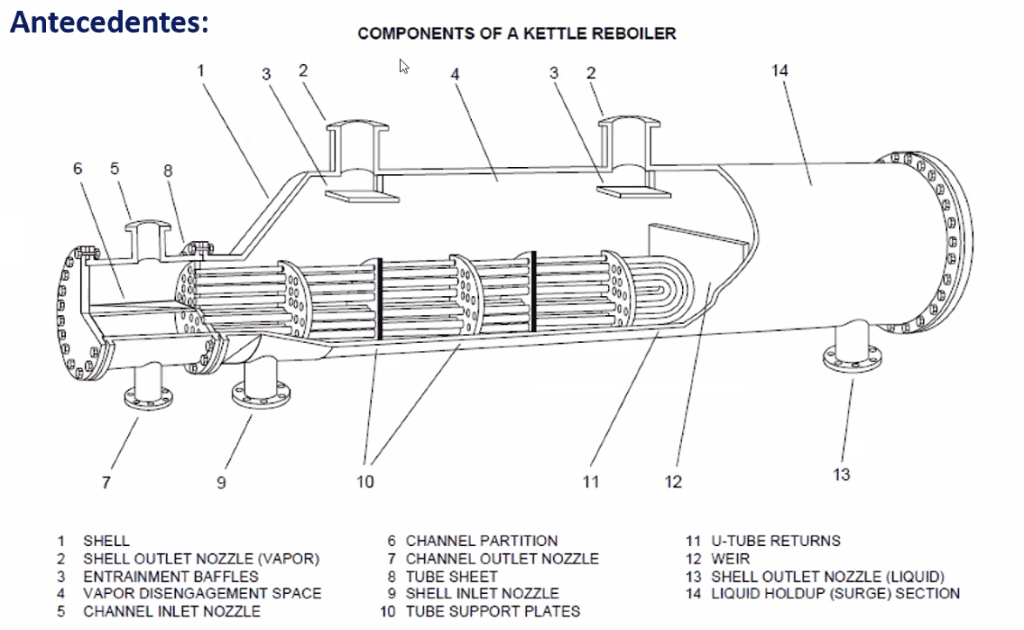

The Kettle reboiler, a cornerstone of distillation columns and vaporization processes, is recognized for its robustness and reliability. However, its optimal performance is not a matter of chance; it is the result of a meticulous design process that considers every detail, from the internal tube layout to the sizing of the vapor space. A superficial

Kettle reboiler design: The impact of tube pitch, pressure drop, and dome sizing Read More »

Kettle reboilers are vital components in the process industry, especially in distillation columns, where their function is to generate the necessary vapor for component separation. However, their design goes far beyond a simple spreadsheet. A suboptimal Kettle reboiler design can translate into operational inefficiencies, high energy consumption, and, in the worst-case scenario, unplanned plant shutdowns

At the heart of every distillation column in the chemical, petrochemical, or refining industry lies a critical piece of equipment: the reboiler. Its function is simple in theory—to generate the vapor that drives the separation—but the reality of its design and operation is profoundly complex. An incorrect design decision at this stage can create a

Kettle reboiler design: A complete guide to efficiency and reliability. Read More »

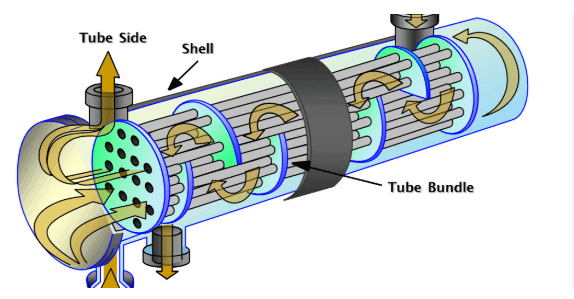

In the intricate network of a process plant, heat exchangers are vital components. However, their optimal performance can be compromised by a critical factor: pressure drop (ΔP). An excessive ΔP is not just a technical concern; it’s a symptom of inefficiency that translates directly into higher operating costs, increased energy consumption, and potentially, a reduced

In the critical infrastructure of nearly every industrial process, from refineries to food plants, lies an essential component: the heat exchanger. Its efficient operation is fundamental to the profitability and safety of any operation. However, to ensure the reliability of each unit, there is a critical phase whose complexity is often underestimated: design based on

TEMA standards for shell and tube heat exchangers: maximizing efficiency and safety Read More »

At the heart of every industrial process operates a silent and costly enemy: fouling in heat exchangers. This phenomenon, the progressive accumulation of unwanted deposits on heat transfer surfaces, is the root cause of countless operational overruns and unscheduled plant shutdowns. It is a critical artery that slowly clogs, choking the performance, efficiency, and profitability

The complete guide to heat exchanger fouling: diagnosis, prevention, and robust design Read More »

At the heart of nearly every process plant lies a component whose performance quietly dictates the efficiency and profitability of the entire operation: the heat exchanger. A successful design is invisible, operating flawlessly for years. A poor design, however, becomes a chronic source of problems—escalating energy costs, production bottlenecks, and plant shutdowns that should never

The ultimate guide to shell and tube heat exchanger thermal design Read More »