Heat exchanger engineering that eliminates plant shutdowns and reduces operational costs.

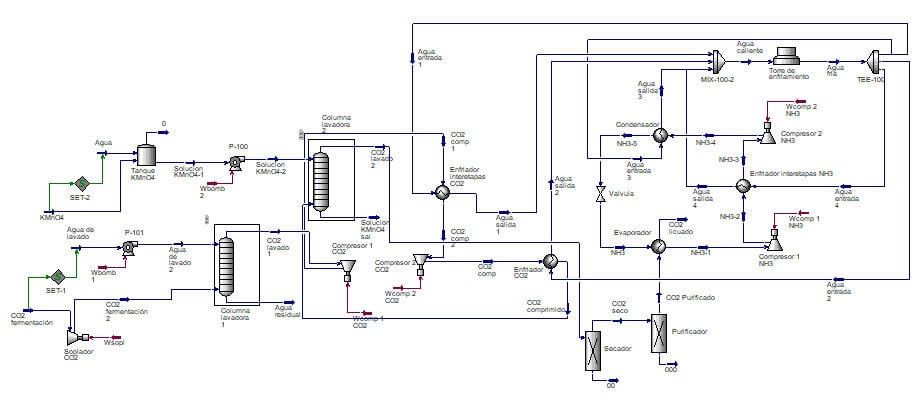

We specialize in heat exchanger design and process simulation services (Aspen HYSYS & EDR) to ensure optimal thermal performance and long-term reliability.

Proven experience in high-demand industries

Oil & Gas · Chemical Processing · Power Generation · Food & Beverage · Pharmaceuticals · Refrigeration & HVAC

Your thermal process could be a silent drain on profitability.

An underperforming heat exchanger isn’t just a faulty piece of equipment; it’s a constant risk. It leads to unplanned maintenance cycles, off-spec products, and energy consumption that erodes your profit margins day after day. Every hour of downtime is an irrecoverable loss. Transform your thermal process into a reliable production asset.

Eliminate plant shutdowns

We design robust equipment that operates reliably under your plant's real-world conditions.

Reduce your energy consumption

Precise thermal optimization translates directly into lower energy costs and higher profitability.

Meet your project deadlines

Accurate engineering from the start prevents costly redesigns and delays.

Invest in long-term quality

Our designs ensure a long service life and sustained performance.

Advanced simulation with Aspen HYSYS

The difference is precision: our technological advantage.

We create a “digital twin” of your process to model operating conditions statically or dynamically. This allows us to obtain the most critical values the process will be subjected to, design the equipment, and then validate its behavior under partial loads to ensure flawless performance in any scenario.

Imagine the peace of mind knowing your equipment has been virtually tested before a single part is manufactured.

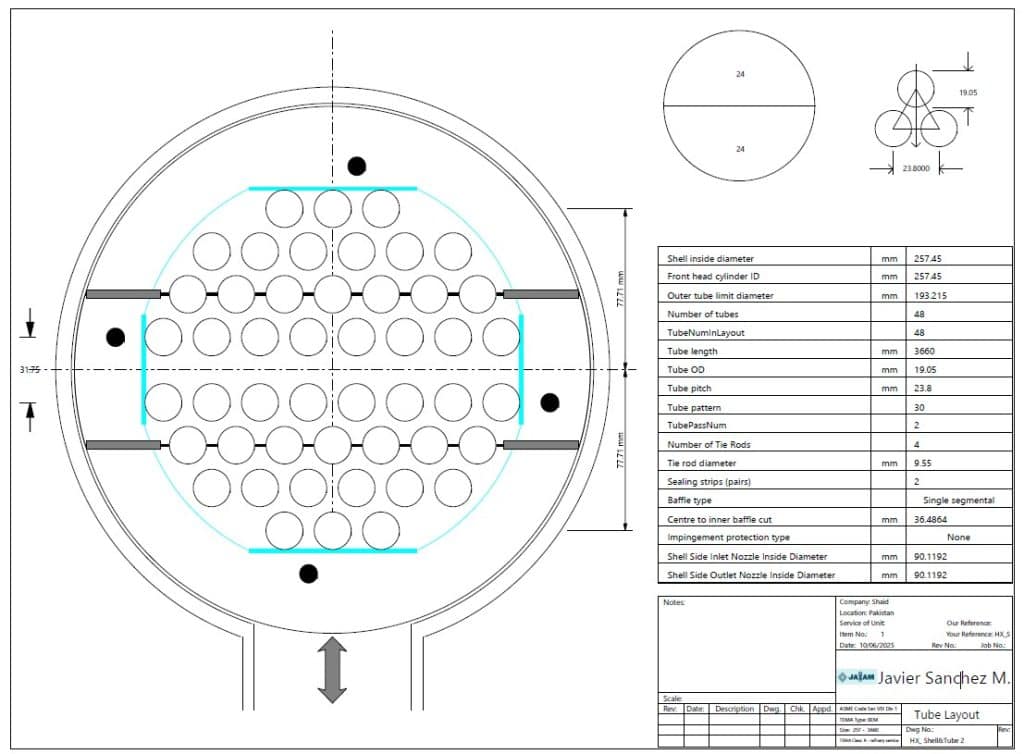

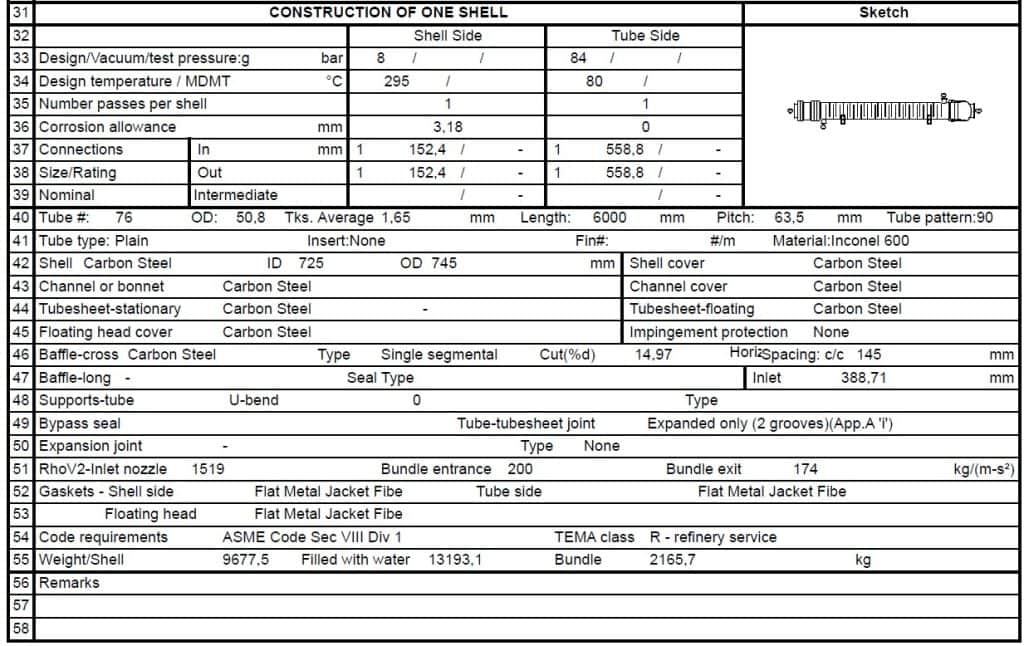

Detailed engineering with Aspen EDR

We use Aspen EDR for detailed design and rating. This allows us to optimize the total cost of ownership (CAPEX and OPEX) and mitigate critical risks like flow-induced vibration, a common cause of mechanical failures.

This detailed approach is fundamental to a successful heat exchanger design.

Have an existing unit? We validate its new application.

The difference is precision: our technological advantage.

If you plan to repurpose an existing heat exchanger for a new process, ensuring its viability is crucial. Using Aspen EDR’s “Simulation” mode, we input your current equipment’s parameters and simulate how it will perform under new working conditions and with new fluids.

We provide the assurance that the equipment will function correctly in its new role, allowing you to save costs and make informed decisions.

Specialized engineering for your most critical applications

Shell and tube heat exchangers

The robust and versatile solution for high pressures and temperatures in chemical, oil, and gas processes.

Kettle type reboilers

Designed for stable and efficient vaporization, ideal for distillation columns and refining processes.

Plate heat exchangers

The compact, high-efficiency option for clean fluids and tight temperature approaches, as in HVAC and food processing.

Our process: collaboration and precision at every stage

Analysis and requirements

We gather your process data and objectives.

Creation of "design basis"

We draft a formal document with key parameters for your approval.

Detailed design and simulation

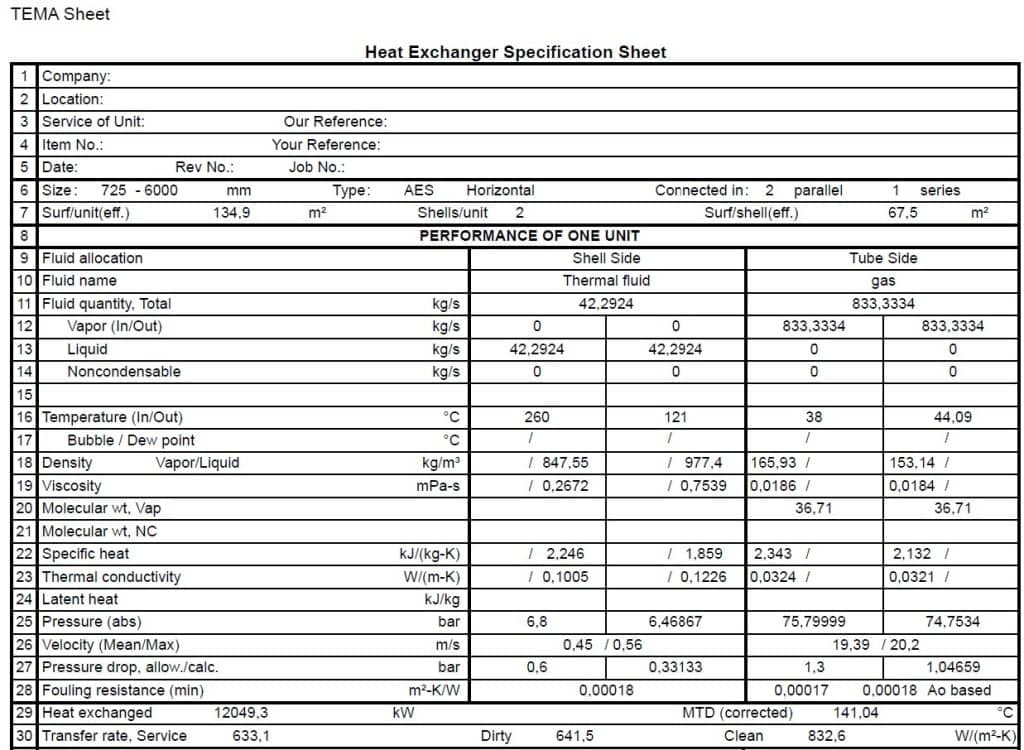

We perform the engineering and generate the TEMA sheet for your validation.

Final engineering delivery

With the TEMA sheet approved, we generate the GA drawings and final package.

What does our design service consist of?

Our work focuses on transforming your process requirements into a complete and optimized heat exchanger design engineering design. Based on the information you provide, we proceed to dimension the most suitable heat exchanger for your application. This comprehensive service includes determining critical parameters such as:

The optimal heat transfer area for your process.

The shell diameter and tube length (for shell and tube heat exchangers).

The tube count, diameter, and layout to maximize efficiency and facilitate maintenance.

The overall equipment configuration, including baffle type and orientation.

The final result of our service is a robust engineering package that includes the equipment’s general arrangement drawings. This technical documentation serves as the foundation that a fabrication company will use to develop detailed fabrication drawings, ensuring the final equipment will meet and even exceed your process demands.

Deliverables that guarantee a global quality standard

- TEMA specification sheet.- The industry standard that ensures universal understanding. Any manufacturer worldwide can accurately quote and build your equipment based on our design.

- General arrangement (GA) drawings These facilitate the seamless integration of the equipment into your plant, detailing dimensions, connections, and structure for a surprise-free installation.

What our clients say

Frequently asked questions

Ideally, we need to know the fluids involved, their flow rates, desired inlet/outlet temperatures, and operating pressures. If you don’t have all the data, don’t worry, we can help you define them during the initial consultation.

A standard thermal and mechanical design, from the approval of the design basis to the delivery of the TEMA sheet, typically takes 5 to 10 business days, depending on the project’s complexity.

Absolutely. Our deliverables are based on universal standards like TEMA and ASME. This ensures that any qualified manufacturer in the world can interpret the drawings and build the equipment with precision.

Your investment, protected. Your trust, our commitment.

We work with a clear and transparent milestone-based payment system. For your complete peace of mind, we offer to manage the project through a trusted third-party escrow service, which protects your investment until you approve each deliverable.

Don't let a poor design compromise your production.

The first step towards a reliable and profitable thermal solution is a simple conversation. Your initial consultation is free and without obligation.